Wooley Tube Bending Service

Wooley's bending process in tube manufacturing involves shaping metal tubes or pipes into specific curves, angles, or shapes. See

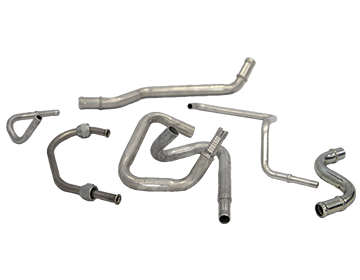

This process is crucial in various industries where customized or complex tube structures are required, such as in construction, automotive, aerospace, and furniture manufacturing.

The first step is to choose the appropriate material for the tubes based on the application requirements. Common materials include steel, aluminum, stainless steel, and copper.

Before bending, the tubes need to be prepared. This involves cutting the tubes to the required length and ensuring that the ends are clean and free from any imperfections.

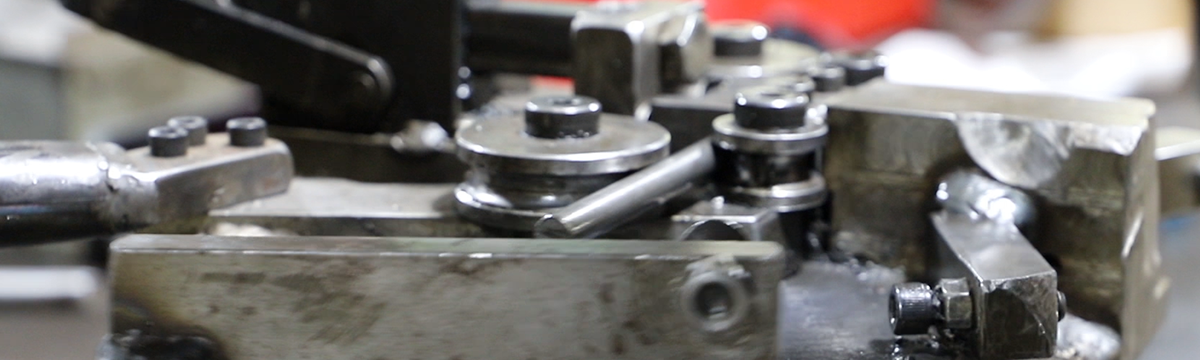

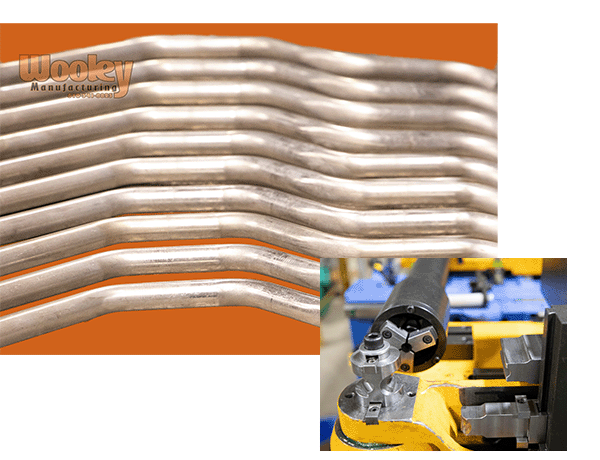

Bending machines, also known as tube benders, are used to shape the tubes. The machine is set up according to the desired bend radius, angle, and the specific tube dimensions. Modern bending machines can be CNC-controlled for precision. At Wooley, we use both manual and automated bending operations.

Depending on the application, mandrel or mandrel-less bending methods may be used. A mandrel is a rod placed inside the tube during bending to prevent it from collapsing or wrinkling. Mandrel-less bending is suitable for less critical applications where a smooth interior surface is not essential.

The tube is securely clamped in the bending machine. The bending process can be performed using different methods, such as rotary draw bending, compression bending, or roll bending. The machine exerts force on the tube, causing it to bend gradually to the specified angle and radius.

Throughout the bending process, quality control measures are implemented to ensure that the tube maintains its structural integrity and dimensional accuracy. Inspections may include checking for defects, wall thickness consistency, and proper bend angles.

After bending, some materials exhibit "spring-back," where the tube tends to return partially to its original shape. Compensation for spring-back is considered in the initial setup of the bending machine to achieve the desired final shape accurately.

Depending on the application, additional processes such as end forming, welding, or surface finishing may be applied to the bent tubes to meet specific requirements.

Once the tubes are successfully bent and meet quality standards, they are packaged and prepared for shipping to the end-user or further manufacturing processes.

If your bending process requires precision, skill and quality control measures to meet your criteria, get in touch. We Just Work!

Rear more, Wooley's Custom Tube Bending in Automotive

Ready to Get Started?

✓ Free quotes within 1 business day

✓ 70+ years of manufacturing experience

✓ Serving Michigan and surrounding states

✓ Prototype to high-volume production

Get A Quote

Advanced CNC Tube Bending

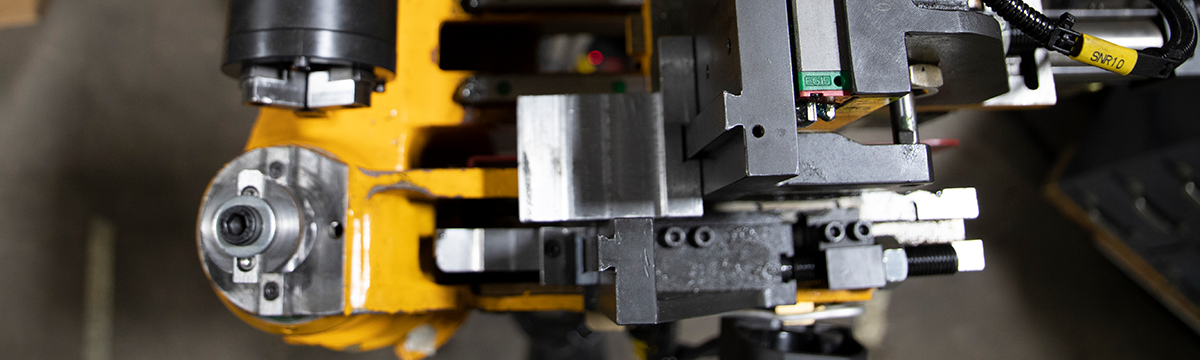

At Wooley Manufacturing, we specialize in precision tube bending services powered by the Horn Metric CNC18MBE, a hybrid CNC tube bender engineered for high-performance and tight-tolerance applications. Whether you're working with mild steel, stainless steel, or non-ferrous metals, our CNC tube bending capabilities ensure consistent, repeatable results across complex geometries and demanding specifications.

Key Features of our Horn Tube Bender

- Hybrid Electric/Hydraulic Drive: Combines servo-electric bending and tube positioning with hydraulic tooling actuation for optimal control and force.

- Dual-Stack Tooling: Enables both mandrel bending for tight radii and roll bending for large-radius sweeps.

- BendPro CNC Controls: Offers full simulation capabilities for precision programming and reduced setup time.

- Servo-Driven Axes:

- Bend-arm (C-axis) via planetary transmission

- Carriage (Y-axis) with push-roll capability

- Collet (B-axis) rotation for multi-plane bending

- Hydraulic Tooling Actuation: Clamp, pressure die, and mandrel systems are hydraulically driven with early withdrawal for wrinkle-free bends.

- Automatic Mandrel Lubrication & Tube Support: Enhances tool life and bend quality.

- Environmentally Friendly: Low power consumption, reduced noise, and minimal heat output.

Serving Michigan, Ohio, and Indiana Automotive Manufacturers

We provide custom tube bending services tailored to the needs of the automotive corridor stretching from Detroit and Flint to Toledo, Cleveland, and Indianapolis. When manufacturers need reliable automotive tube bending, they turn to specialists with decades of experience serving "Automotive Corridor". Our team delivers custom-engineered tubing solutions that meet the highest standards for strength, durability, and fit.

- Capabilities;

- Prototype development for new models

- High-volume production runs

- Tight tolerance CNC bending

- Material expertise across steel, stainless, and aluminum

- Why Us?

- Advanced CNC tube bending machinery

- Automotive quality standards compliance

- Serving Great Lakes Automotive Corridor OEM suppliers

- Fast turnaround for just-in-time manufacturing