This section will house all of our blog post material about tube manufacturing!

Trusted Partner to Tier 1 and Tier 2 Suppliers

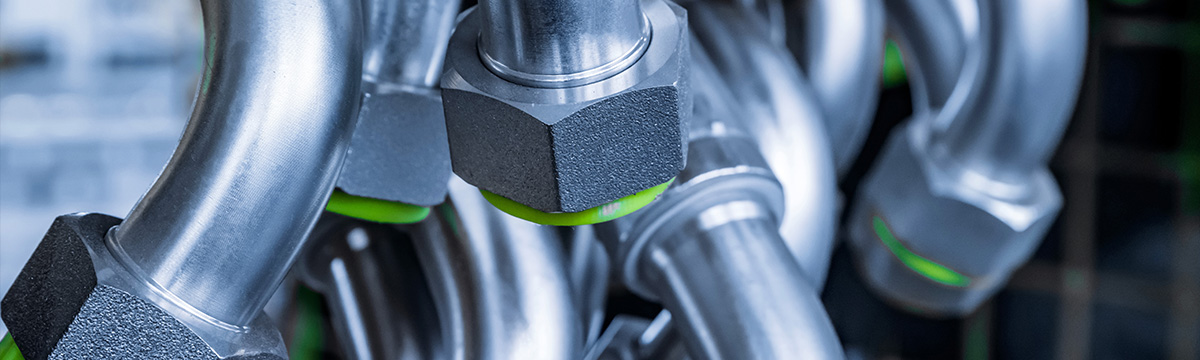

As a dedicated Tier 2 supplier for tube fabrication, we support major automotive manufacturers throughout Detroit, Toledo, and Cleveland. Our fabrication services integrate seamlessly into the supply chain, providing the precision and consistency Tier 1 suppliers demand.

Tube Fabrication Capabilities

- CNC tube cutting more about tube cutting

- End forming more about end forming

- Swaging

- Flaring

- Prototyping and production runs

- Material certifications for automotive standards

Read more: Tier 2 Tube Fabrication for Automotive & Industrial Suppliers