Trusted Partner to Tier 1 and Tier 2 Suppliers

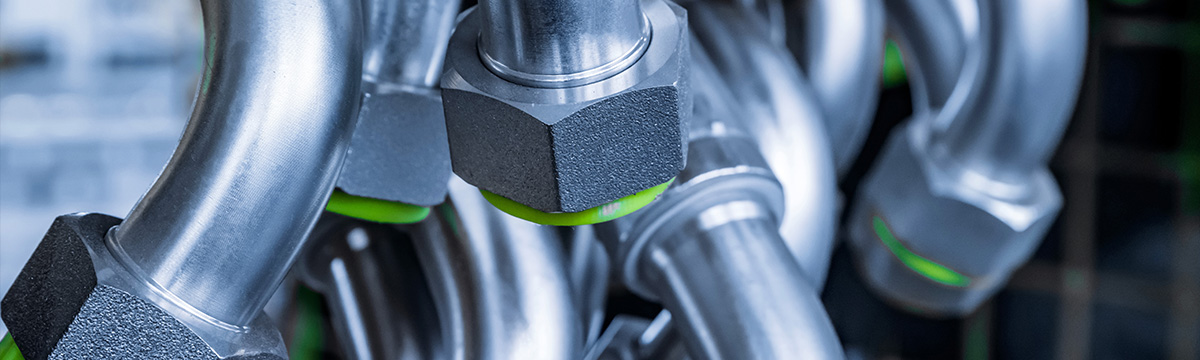

As a dedicated Tier 2 supplier for tube fabrication, we support major automotive manufacturers throughout Detroit, Toledo, and Cleveland. Our fabrication services integrate seamlessly into the supply chain, providing the precision and consistency Tier 1 suppliers demand.

Tube Fabrication Capabilities

- CNC tube cutting & forming

- End forming, swaging, and flaring

- Prototyping and production runs

- Material certifications for automotive standards

Serving the Midwest Automotive Corridor

We are strategically positioned near Michigan, Ohio, and Indiana manufacturing hubs, allowing us to meet strict deadlines with regional delivery.

Partner with us for Tier 2 tube fabrication that keeps your automotive programs on schedule.

Advanced Tube Forming for Aerospace Applications

We provide precision aerospace tube forming for suppliers throughout the Great Lakes region, including Detroit, Cleveland, and Indianapolis. Our specialized processes meet strict aerospace standards for accuracy, safety, and performance.

Capabilities for Aerospace Tubing

- Tight-tolerance CNC tube bending

- Exotic alloy forming (titanium, Inconel, stainless)

- Prototype and certified production runs

- NADCAP-ready processes

Supporting Aerospace Manufacturing in the Midwest

Our location in the Great Lakes corridor makes us a strong partner for aerospace companies looking for reliable suppliers in Michigan, Ohio, and Indiana.

Contact us today for aerospace tube forming in the Great Lakes region and get aerospace-grade precision.

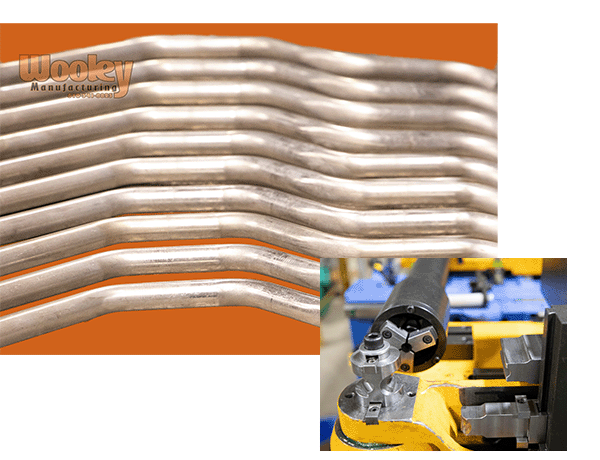

Serving Michigan, Ohio, and Indiana Automotive Manufacturers

We provide custom tube bending services tailored to the needs of the automotive corridor stretching from Detroit and Flint to Toledo, Cleveland, and Indianapolis. When manufacturers need reliable automotive tube bending, they turn to specialists with decades of experience serving "Automotive Corridor". Our team delivers custom-engineered tubing solutions that meet the highest standards for strength, durability, and fit.

Capabilities Prototype development for new models High-volume production runs Tight tolerance CNC bending Material expertise across steel, stainless, and aluminum Why Us? Advanced CNC tube bending machinery Automotive quality standards compliance Serving Great Lakes Automotive Corridor OEM suppliers Fast turnaround for just-in-time manufacturing

Why the Corridor Trusts Us

Our central location allows us to supply multiple states quickly, helping keep just-in-time production on track for Tier 1 and Tier 2 suppliers. As a trusted supplier in the Michigan automotive supply chain, we work closely with Tier 1 and Tier 2 suppliers. Whether you need short-run prototypes or high-volume production, our CNC tube bending services ensure repeatable accuracy.

For custom tube bending in the automotive corridor, request a quote today.

Precision Tube Cutting for Heating & Cooling Systems

Our tube cutting services help HVAC manufacturers in Cleveland, Toledo, and Columbus, Ohio deliver high-quality heating and cooling systems. We provide accurate, burr-free cuts that ensure reliable system performance.

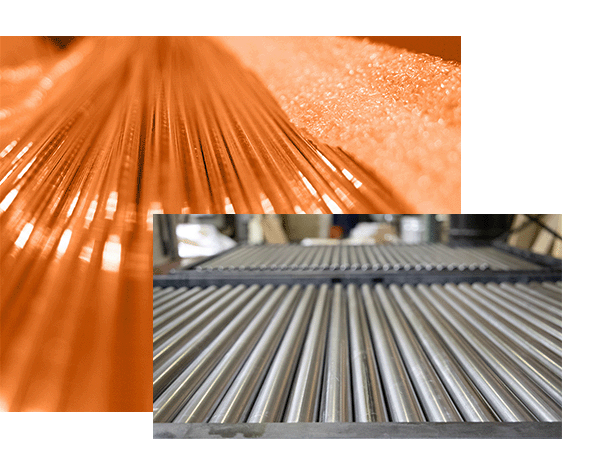

Tube Processing for HVAC Applications

Copper and aluminum tube cutting CNC precision cutting for clean edges Volume runs for HVAC assembly lines Serving Ohio OEM and aftermarket HVAC suppliers

Regional Advantage

Near Cleveland and Toledo, our tube cutting can reduce lead times for HVAC manufacturers across Ohio.

Reach out today to discuss HVAC tube cutting in Ohio and streamline your supply chain.

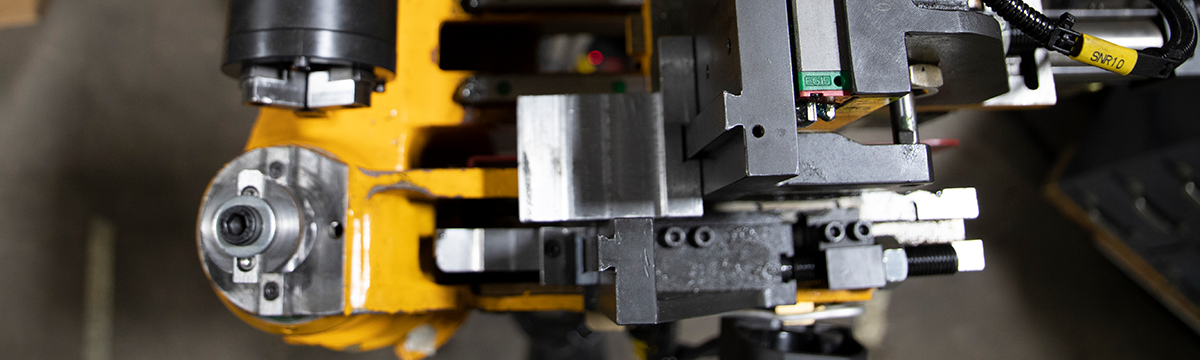

Advanced CNC Tube Bending

At Wooley Manufacturing, we specialize in precision tube bending services powered by the Horn Metric CNC18MBE, a hybrid CNC tube bender engineered for high-performance and tight-tolerance applications. Whether you're working with mild steel, stainless steel, or non-ferrous metals, our CNC tube bending capabilities ensure consistent, repeatable results across complex geometries and demanding specifications.

Key Features of our Horn Tube Bender

- Hybrid Electric/Hydraulic Drive: Combines servo-electric bending and tube positioning with hydraulic tooling actuation for optimal control and force.

- Dual-Stack Tooling: Enables both mandrel bending for tight radii and roll bending for large-radius sweeps.

- BendPro CNC Controls: Offers full simulation capabilities for precision programming and reduced setup time.

- Servo-Driven Axes:

- Bend-arm (C-axis) via planetary transmission

- Carriage (Y-axis) with push-roll capability

- Collet (B-axis) rotation for multi-plane bending

- Hydraulic Tooling Actuation: Clamp, pressure die, and mandrel systems are hydraulically driven with early withdrawal for wrinkle-free bends.

- Automatic Mandrel Lubrication & Tube Support: Enhances tool life and bend quality.

- Environmentally Friendly: Low power consumption, reduced noise, and minimal heat output.

Tube Bending Specifications

Tube Bending Tolerances

Our CNC tube bending process adheres to industry-standard tolerances, including:

- Bend Angle Accuracy: ±0.25°

- Bend Radius Consistency: ±0.010 in (±0.25 mm)

- Ovality Control: Maintained within ±10% of nominal diameter

- Wall Thinning: Typically less than 15%, depending on material and bend radius

- Repeatability: High precision across production runs due to servo-controlled motion and CNC programming

- Automotive and Off-Road

- HVAC and Refrigeration

- Aerospace and Defense

- Medical Equipment

- Industrial Machinery

Applications

Our tube bending services support a wide range of industries, including:

Whether you need prototype development, low-volume production, or high-volume manufacturing, our CNC tube bending capabilities deliver unmatched precision and efficiency.

Request a Quote or Consultation Ready to get started? Contact us today to discuss your project requirements or request a quote for custom tube bending services