Precision Tube Cutting, Deburring, End Forming & Bending | Wooley Manufacturing | Flint, MI

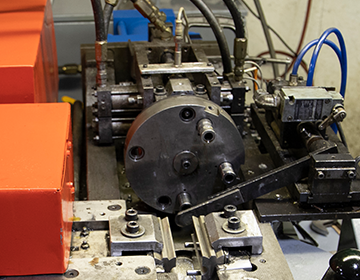

Precision Tube Cutting Services

At Wooley Manufacturing, tube cutting isn't just a service—it's our foundation. Our state-of-the-art tube cutting equipment handles materials from 1/8" to 4" diameter with repeatable accuracy and clean, square cuts every time. We work with steel, stainless steel, aluminum, brass, copper, and specialty alloys to meet your exact specifications.

Our precision tube cutting capabilities include:

- High-volume production cutting** for HVAC manufacturers, automotive suppliers, and industrial equipment makers

- Prototype tube cutting** with fast turnaround for R&D and product development

- Tight tolerance cutting** to ±0.010" for applications requiring exact lengths

- Multi-length cutting** for complex assemblies requiring various tube lengths

- Clean, burr-minimized cuts** that reduce secondary operations

Whether you're sourcing tube cutting services for a single test piece or need 100,000 tubes cut to precise lengths monthly, our capacity and flexibility make us the ideal tube cutting supplier. Our location in Flint, Michigan provides quick access to major manufacturing centers throughout the Great Lakes corridor, reducing lead times for time-sensitive projects.

Professional Tube Deburring

Clean edges aren't optional—they're essential. Our tube deburring services ensure your parts are assembly-ready with smooth, safe edges that meet or exceed your quality standards. We understand that burrs can cause assembly problems, create safety hazards, and compromise the integrity of welded or brazed joints.

Wooley Manufacturing's deburring capabilities include:

- Internal deburring** to remove burrs from tube interior surfaces

- External deburring** for clean outer diameter edges

- End deburring** for both tube ends to specified finish requirements

- High-volume deburring** processing thousands of pieces with consistent quality

- Material-specific deburring** techniques optimized for steel, stainless, aluminum, and other alloys

Our deburring processes prepare tubes perfectly for secondary operations like welding, brazing, coating, or final assembly. If you're tired of dealing with tube suppliers who deliver parts with rough edges that slow down your production line, experience the Wooley difference. We deliver deburred tubes that go straight into your assembly process without additional handling.

Tube BendingOur team delivers custom-engineered tubing solutions that meet the highest standards for strength, durability, and fit.

Tube BendingOur team delivers custom-engineered tubing solutions that meet the highest standards for strength, durability, and fit.

End Forming

Our location in the Great Lakes corridor makes us a strong partner for tube end forming supplier in Michigan, Ohio, and Indiana.

End Forming

Our location in the Great Lakes corridor makes us a strong partner for tube end forming supplier in Michigan, Ohio, and Indiana.

Tube Cutting

Our tube cutting can reduce lead times for HVAC manufacturers across Ohio and Michigan.

CNC MachiningFrom design to final inspection, each step is crucial in ensuring the efficiency and accuracy of the machining process.

CNC MachiningFrom design to final inspection, each step is crucial in ensuring the efficiency and accuracy of the machining process.

Custom Tube End Forming

Tube end forming is where craftsmanship meets engineering precision. Wooley Manufacturing specializes in complex tube end forming operations that transform standard tube ends into functional components. Our end forming capabilities allow us to create flared ends, expanded ends, reduced ends, beaded ends, and custom profiles that eliminate the need for separate fittings or additional components.

Our tube end forming services include:

- Flaring and expanding** for fluid connections and assembly interfaces

- Tube reducing** to create diameter transitions within a single piece

- Beading and swaging** for mechanical locking and sealing applications

- Custom profile forming** to match your unique design requirements

- Multi-step end forming** for complex geometries requiring sequential operations

As a leading tube end forming supplier in Michigan, we serve automotive manufacturers, HVAC producers, hydraulic system builders, and industrial equipment makers who demand precision-formed tube ends. Our end forming expertise means you can consolidate suppliers, reduce assembly costs, and improve product performance with properly formed tube components.

Complete Tube Fabrication Solutions

While tube cutting, deburring, and end forming are our primary specialties, Wooley Manufacturing offers comprehensive tube fabrication services to be your single-source solution.

Tube Bending Services

Our precision tube bending capabilities handle simple to complex bends with accuracy and repeatability. Using modern CNC tube benders and traditional mandrel bending equipment, we produce bent tubes for automotive exhaust systems, hydraulic lines, HVAC coils, roll cages, and custom assemblies.

Tube bending capabilities:

- Radius bending from 1" to 12" centerline radius

- Multi-plane bends for complex routing requirements

- Mandrel bending to prevent tube collapse and maintain flow characteristics

- Rotary draw bending for tight-radius applications

- Production bending with consistent quality across thousands of pieces

CNC Drilling and Machining

When your tube components require precision holes, slots, or machined features, our CNC drilling and machining services deliver exact placement and sizing. We drill mounting holes, create slots for mounting brackets, machine flats for secure connections, and add threaded features—all while maintaining tube integrity.

Metal Tube Shaping and Forming

Beyond end forming, our metal tube shaping capabilities include flattening, notching, piercing, and profile forming. These tube shaping operations allow us to create tubes that fit precisely into your assemblies, eliminating costly hand-fitting during production.

Tube Welding and Brazing

Complete your tube assemblies with our professional welding and brazing services. We perform TIG welding, MIG welding, and brazing operations on tube-to-tube connections, tube-to-fitting assemblies, and custom fabrications. Our certified welders ensure leak-free, strong joints that meet your pressure and durability requirements.

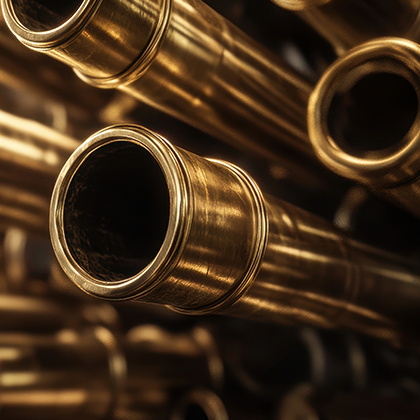

Materials We Process

Wooley Manufacturing works with virtually any tubular material your application requires:

- Carbon Steel Tubing** - DOM, welded, seamless in various grades

- Stainless Steel Tubing** - 304, 316, 321 for corrosion resistance

- Aluminum Tubing** - 6061, 6063, 3003 for lightweight applications

- Brass & Copper Tubing** - For plumbing, HVAC, and decorative applications

Industries We Serve

Our tube cutting, deburring, and end forming services support manufacturers across diverse industries:

- Automotive Manufacturing** - Exhaust systems, fuel lines, brake lines, chassis components, cooling systems

- HVAC & Refrigeration** - Coils, manifolds, refrigerant lines, heat exchangers

- Hydraulic & Pneumatic Systems** - High-pressure lines, cylinders, fluid power components

- Industrial Equipment** - Machine frames, conveyor systems, structural components

- Medical Devices** - Surgical instruments, patient handling equipment, medical furniture

- Furniture & Fixtures** - Commercial furniture, retail displays, architectural elements

Why Choose Wooley Manufacturing?

Decades of Tube Fabrication Experience

Since the mid-20th century, we've been solving tube fabrication challenges for manufacturers throughout the Great Lakes region. Our experience means we understand the technical specifications, tolerances, and quality standards your applications demand. We eat, sleep, and breathe technical specs—and we love surprising customers with our precision.

Strategic Great Lakes Location

Located in Flint, Michigan, Wooley Manufacturing sits at the heart of America's manufacturing corridor. Our location provides rapid access to major manufacturing centers in Michigan, Ohio, Indiana, and throughout the Midwest. This geographic advantage translates to reduced shipping costs and faster lead times for your tube cutting, deburring, and end forming projects.

Flexible Production Capacity

From single prototypes to high-volume production runs, we scale our operations to match your needs. Need one test piece tomorrow? We can do that. Need 10,000 deburred tubes weekly for the next year? We can handle that too. Our flexibility makes us an ideal partner whether you're a startup developing your first product or a tier-2 supplier serving major OEMs.

Real Humans, Real Partnership

You haven't met a team like ours. At Wooley Manufacturing, we're real humans working to accomplish goals together with other real humans. No automated phone systems, no frustrating portals—just direct communication with people who care about getting your parts right. After working with us, we'll be fast friends. We're the breath of fresh air you've been looking for in a manufacturing partner.

Quality Without Compromise

Every tube we cut, every edge we deburr, every end we form goes through our rigorous quality process. From material procurement through final inspection, each step ensures the efficiency and accuracy your applications require. We deliver parts that are exactly right, exactly where they need to be, at prices that make you smile.

Our Complete Service Portfolio

Tube Fabrication Services:- Precision tube cutting

- Professional tube deburring

- Custom tube end forming

- Tube bending

- Metal tube shaping

- CNC drilling and machining

- Tube welding and brazing

Support Services:

- Material procurement and supply

- Engineering consultation and design support

- Prototyping and short-run production

- Quality testing and inspection

- MATE (Material As Tested and Evaluated) documentation

- Production scheduling and inventory management

From Prototype to Production: We Scale With You

Whether you're developing a new product or ramping up existing production, Wooley Manufacturing adapts to your project lifecycle. Our prototyping services allow you to test designs quickly with small quantities. When you're ready for production, we seamlessly transition to high-volume manufacturing without changing suppliers or requalifying processes.

This prototype-to-production capability is especially valuable for:

- Product development teams needing rapid iterations

- Engineers testing multiple design variations

- Manufacturers transitioning from low-volume to high-volume production

- Companies entering new markets with phased rollouts

Get Started With Wooley Manufacturing

Ready to experience precision tube cutting, professional deburring, and expert end forming services? Contact Wooley Manufacturing today for a quote on your project. Our team will review your specifications, recommend the optimal processes, and provide competitive pricing with realistic lead times.

Contact us for:- Free project quotes

- Technical consultation

- Material recommendations

- Process capability discussions

- Facility tours

- Sample parts evaluation

Located in Flint, Michigan, serving manufacturers across the Great Lakes region and nationwide. When you need tube cutting, deburring, and end forming done right—we're the team that delivers.

Wooley Manufacturing - We Just Work!