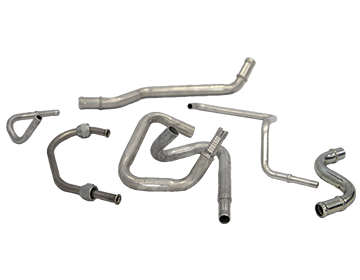

Wooley's bending process in tube manufacturing involves shaping metal tubes or pipes into specific curves, angles, or shapes.

This process is crucial in various industries where customized or complex tube structures are required, such as in construction, automotive, aerospace, and furniture manufacturing.

The first step is to choose the appropriate material for the tubes based on the application requirements. Common materials include steel, aluminum, stainless steel, and copper.

Before bending, the tubes need to be prepared. This involves cutting the tubes to the required length and ensuring that the ends are clean and free from any imperfections.

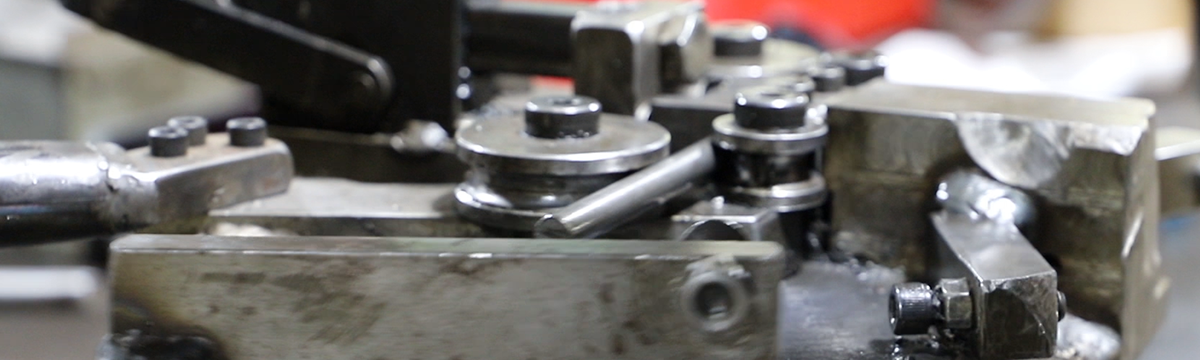

Bending machines, also known as tube benders, are used to shape the tubes. The machine is set up according to the desired bend radius, angle, and the specific tube dimensions. Modern bending machines can be CNC-controlled for precision. At Wooley, we use both manual and automated bending operations.

Depending on the application, mandrel or mandrel-less bending methods may be used. A mandrel is a rod placed inside the tube during bending to prevent it from collapsing or wrinkling. Mandrel-less bending is suitable for less critical applications where a smooth interior surface is not essential.

The tube is securely clamped in the bending machine. The bending process can be performed using different methods, such as rotary draw bending, compression bending, or roll bending. The machine exerts force on the tube, causing it to bend gradually to the specified angle and radius.

Throughout the bending process, quality control measures are implemented to ensure that the tube maintains its structural integrity and dimensional accuracy. Inspections may include checking for defects, wall thickness consistency, and proper bend angles.

After bending, some materials exhibit "spring-back," where the tube tends to return partially to its original shape. Compensation for spring-back is considered in the initial setup of the bending machine to achieve the desired final shape accurately.

Depending on the application, additional processes such as end forming, welding, or surface finishing may be applied to the bent tubes to meet specific requirements.

Once the tubes are successfully bent and meet quality standards, they are packaged and prepared for shipping to the end-user or further manufacturing processes.

If your bending process requires precision, skill and quality control measures to meet your criteria, get in touch. We Just Work!

Ready to Get Started?

✓ Free quotes within 1 business day

✓ 70+ years of manufacturing experience

✓ Serving Michigan and surrounding states

✓ Prototype to high-volume production

Get A Quote